ARNO - расширение отрезного инструмента 2016 EN

для размещения заказа - info@arno-tools.ru

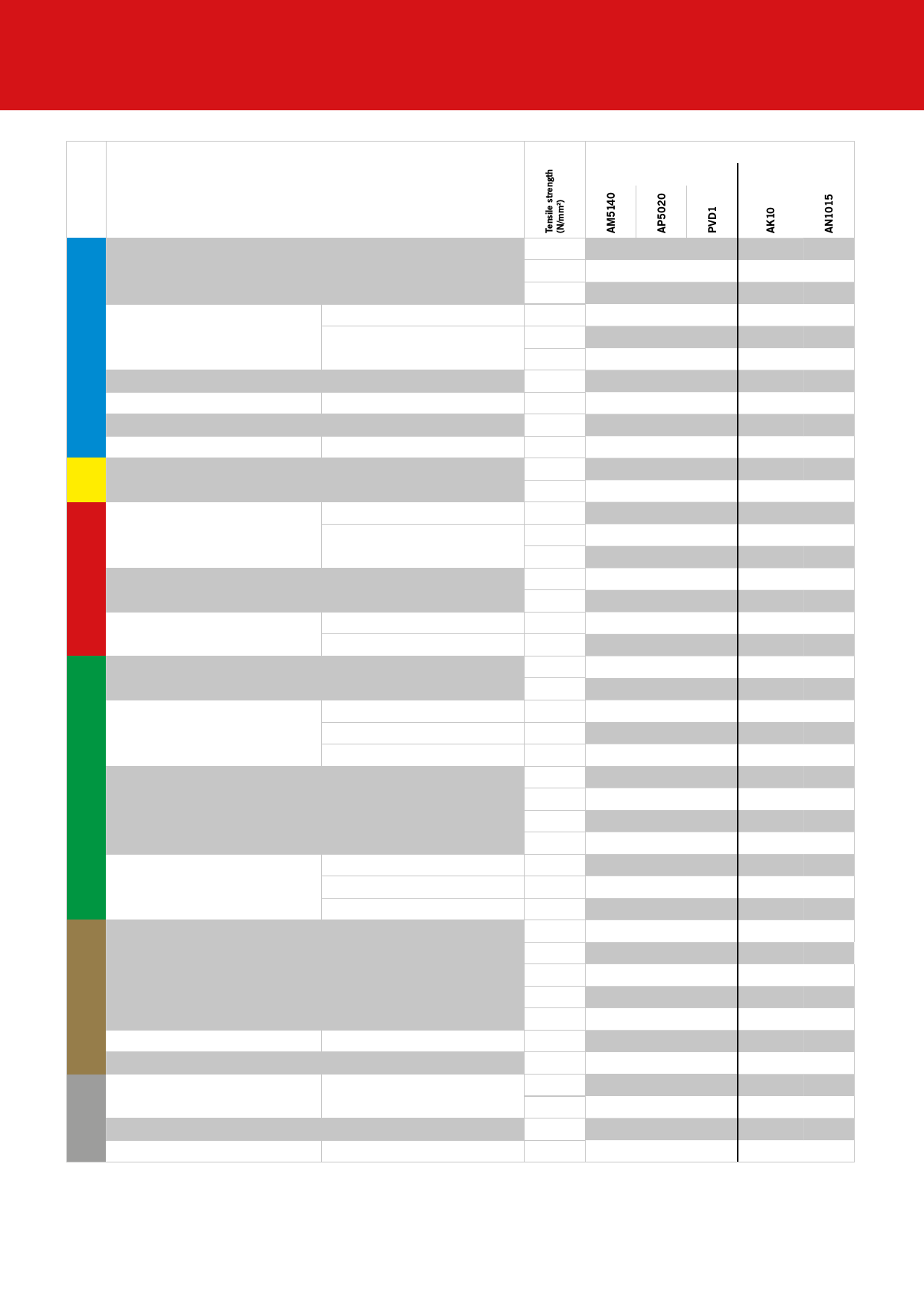

Recommended cutting data

CLIP-GROOVE®

ISO Material

Cutting speed VC (m/min)

coated

uncoated

Unalloyed steel and

cast steel

Low alloyed steel and

P cast steel

High alloyed steel

High alloyed tool steel and cast steel

Stainless steel

Cast steel

M Stainless steel

Cast iron

K Cast iron with nodular graphite

Malleable cast iron

Aluminium alloys long chipping

Casted aluminium alloys

N

Copper and copper alloys

(Brass/Bronze)

Non-ferrous materials

High temperature resistant alloys

S

Titanium alloys

Alpha- and Beta-alloys

Hardened steel

H Hard cast iron

Hardened cast iron

<0.15% C/hardened and tempered

350 120–200 120–220 100–130

–

–

0.15 – 0.45% C/hardened and tempered 650 80–150 80–150 – –

>0.45% C/hardened and tempered

1000 60–140 60–140 60–100

–

–

annealed

600 80–160 80–170 70–110

–

–

hardened and tempered

900

1200

60–130 60–130 60–100

60–120 60–120 50–70

–

–

–

–

annealed

700 80–140 80–140 70–110

–

–

hardened

1100 50–120 50–120 50–70

–

–

ferritic, annealed

700 60–160 60–170 130–200

–

–

martensitic, hardened and tempered

1000 50–100 50–100 60–90

–

–

austenitic and austenitic/

450–600 60–160 60–180 130–200

–

–

ferritic, chilled

600–900 50–90 50–90 60–90

–

–

pearlitic/ferritic

500–700

–

– 140–180 100–180 120–160

pearlitic/martensitic

700–850

800–1100

–

–

– 110–140 90–120 100–150

– 100–140 80–120 90–140

ferritic

550 – – 120–160 100–140 130–170

pearlitic

800 – – 100–140 80–120 90–130

ferritic

450 – – 140–200 70–90 140–200

pearlitic

750 – – 120–160 60–70 120–160

not heat treatable

200 – 100–500 100–800 650–1000 300–500

heat treatable, heat treated

350 – 100–300 100–600 300–700 200–300

12% Si, heat treated

250 – 100–500 100–400 200–600 100–500

12% Si, heat treatable, heat treated 300 – 100–300 100–400 150–400 100–300

12% Si, not heat treatable

450 – 100–200 100–400 100–300 100–200

Lead alloys, Pb>1%

400 – 100–500 80–300 250–600 250–500

Brass, Bronze

300 – 100–500 150–600 205–400 200–500

Aluminium bronze

500 – 100–300 100–400 250–500 150–300

Copper and elektrolyte copper

200 – 100–300 80–300 130–300 150–300

Duroplastice

– – 80–180 80–400 80–500 80–180

Re-inforced plastics

– – 60–150 80–160 60–150 80–200

Hard rubber

– – 100–220 100–300 100–250 100–200

Fe-alloyed, annealed

700 – 20–50 25–40 10–30 70–110

Fe-alloyed, heat treated

950 – 20–40 20–28 15–30 30–60

Ni- or Co-alloyed, annealed

800 – 15–25 12–20 15–30 50–70

Ni- or Co-alloyed, casting

1100

– 10–20 8–16

– 50–70

Ni- or Co-alloyed, heat treated

1200

– 10–20 8–20

– 50–80

Pure titan

500–700

–

50–120

–

15–50 110–160

heat treated

700–1000

–

30–50

–

40–70 25–50

hardened

55 HRC

–

–

–

–

–

60 HRC

–

–

–

–

–

casting

41 HRC

–

–

–

–

–

hardened

55 HRC

–

–

–

–

–

The recommended cutting data are only approximate values.

It may be necessary to adjust them to each individual machining application.

Alle Angaben in mm / Dimensions in mm / Tutte le dimensioni in mm

ARNO®-Werkzeuge | Katalog-Ergnzung | StechenGroovingScanalatura 29

info@arno-tools.ru

www.arno-tools.ru