ARNO - монолитный осевой инструмент 2015 EN

для размещения заказа - info@arno-tools.ru

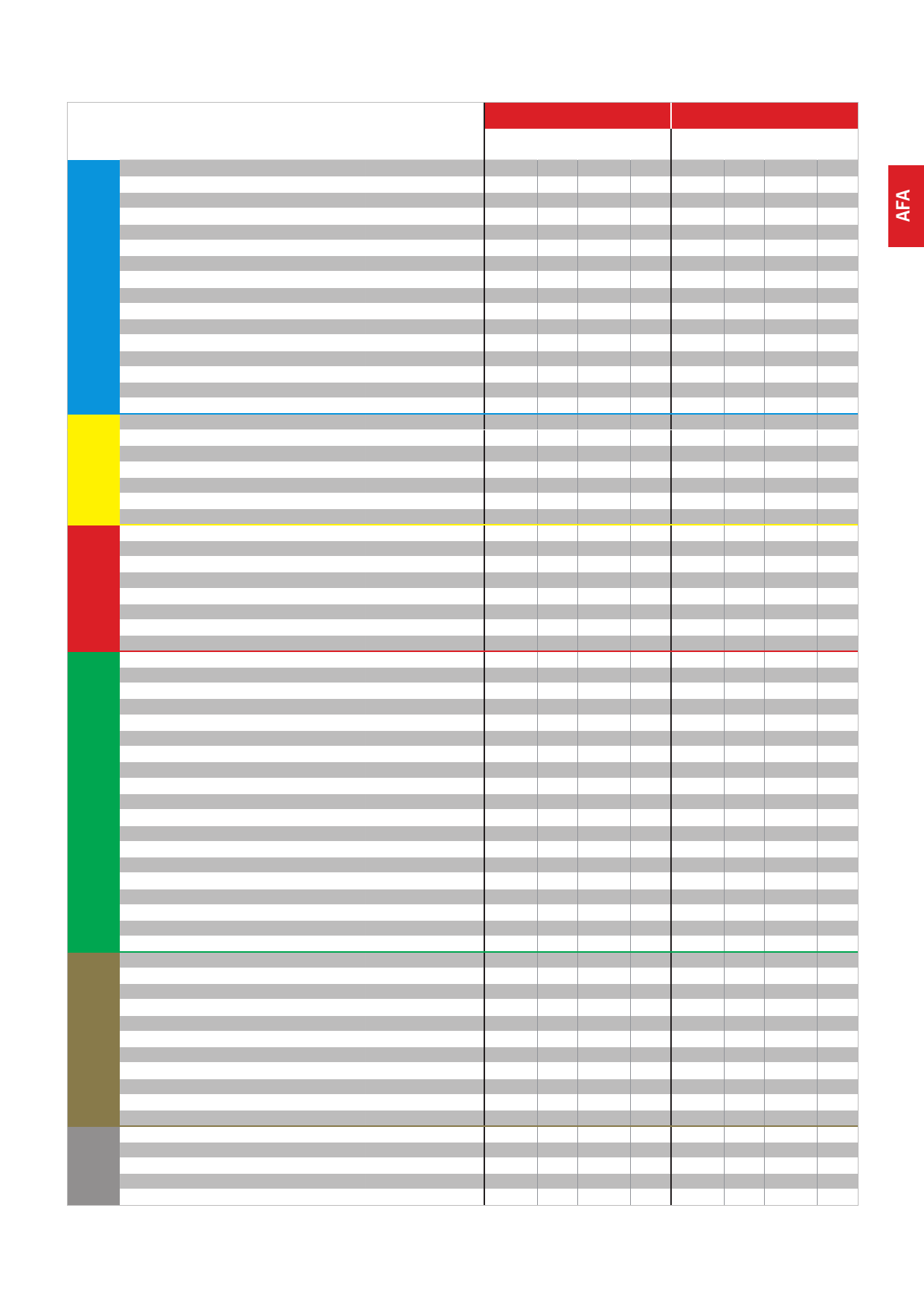

Recommended cutting data Solid carbide end-mill

Design AFA

ISO Material

P

M

K

N

S

H

General construction steel

Free cutting steel

Case hardened steel, non alloyed

Alloyed case hardened steel

Tempering steel, non alloyed

Tempering steel, non alloyed

Tempering steel, alloyed

Tempering steel, alloyed

Steel castings

Nitriding steel

Nitriding steel

Roller bearing steel

Spring steel

High-speed steel

Cold working tool steel

Hot working tool steel

Steel and sulphured cast stainless steel

Stainless steel, ferritic

Stainless steel, martensitic

Stainless steel, ferritic/martensitic

Stainless steel, austenitic/ferritic

Stainless steel, austenitic

Heat resistant steel

Grey cast iron with lamellar graphite

Grey cast iron with lamellar graphite

Speroidal cast iron

Speroidal cast iron

White cast iron, tempered

White cast iron, tempered

Black cast iron, tempered

Black cast iron, tempered

Aluminium (non alloyed, low alloyed)

Aluminium alloys < 0,5% Si

Aluminium alloys 0,5%-10% Si

Aluminium alloys 10%-15% Si

Aluminium alloys > 15% Si

Copper (non alloyed, low alloyed)

Copper wrought alloys

Special copper alloys

Special copper alloys

Special copper alloys

Short-chipping brass, bronze, red bronze

Long-chipping brass

Thermoplastics

Duroplastics

Fibre-reinforced plastics

Magnesium and magnesium alloys

Graphite

Tungsten and tungsten alloys

Molybdenum and molybdenum alloys

Pure nickel

Nickel alloys

Nickel alloys

Nickel-chromium alloys

Nickel and cobalt alloys

Nickel and cobalt alloys

Heat resistant alloys

Nickel-cobalt-chromium alloys

Pure titanium

Titanium alloys

Titanium alloys

Tempered steel

Strength

[N/mm2]

< 800

< 800

< 800

< 1000

< 850

< 1000

< 800

< 1300

< 850

< 1000

< 1200

< 1200

< 1200

< 1300

< 1300

< 1300

< 850

< 750

< 900

< 1100

< 850

< 750

< 1100

100-350

300-1000

300-500

550-800

350-450

500-650

350-450

500-700

< 350

< 500

< 400

< 400

< 400

< 350

< 700

< 200 HB

< 300 HB

> 300 HB

< 600

< 600

< 850

Correction

factor [x fz]

1,9

1,9

1,8

1,7

1,6

1,2

1,1

0,9

0,7

0,7

1,1

1,1

2

2

1

1,8

1

1,1

1

Roughing and full slot milling

uncoated

Vc [m/min]

TiAlN

Vc [m/min]

TiCN

Vc [m/min]

Tia70

Vc [m/min]

250-300

250-300

200-250

150-200

100-150

90-120

80-110

100-150

70-110

60-90

90-120

90-120

50-60

90-100

40-60

100-150

-

50-80

50-80

280-320

280-320

220-270

170-200

120-180

100-130

90-120

120-160

80-120

70-100

100-130

100-130

70-90

120-180

50-70

150-200

100-120

60-80

60-80

Peripheral- and contour milling

uncoated

Vc [m/min]

TiAlN

Vc [m/min]

TiCN

Vc [m/min]

Tia70

Vc [m/min]

500-550

450-500

400-450

300-350

200-250

160-220

140-180

180-220

140-200

120-150

160-220

160-220

100-130

180-210

80-120

150-200

-

70-90

70-90

520-580

500-530

400-480

300-360

200-280

180-240

160-220

200-250

160-250

140-180

180-250

180-250

110-140

200-250

90-140

170-220

150-200

70-100

90-100

< 850

< 1300

< 1300

< 1400

< 1300

< 900

< 700

< 1200

< 45 HRC

46-55 HRC

56-60 HRC

61-65 HRC

65-70 HRC

The recommended cutting data are only approximate values. It may be necessary to adjust them to each individual machining application.

ARNO®-Werkzeuge | VHM-/PM-HSS Werkzeuge | Solid carbide-/PM-HSS Tools 99

info@arno-tools.ru

www.arno-tools.ru